Customized Neodymium (NdFeB) Magnets

For a general quote request please fill out the form below.

CUSTOM NEODYMIUM MAGNETS

VERY Magnet is a leading manufacturer of custom neodymium magnets. Our team can supply all grades of neodymium magnets, custom shapes, sizes, and coatings.

* Mass production of neodymium magnets according to your company specification.

* Custom neodymium magnets

* High quality.

* Optimized performance and cost to your company’s needs.

* Design assistance.

* Free samples.

* REACH & ROHS compliance.

Contact us today for custom-engineered neodymium magnets in any shape and size!

Not only we do offer competitive pricing, but our lead times of 4-6 weeks are convent and reliable for all new and long-time customers.

Some of the most common Neodymium magnets we have provided are N35, N42, N45, N48, N52, and N55.

Click below to see our wide selection of grades available for your specific needs.

Neodymium Iron Boron (NdFeB) magnets are the most commonly used rare-earth magnets and are made from 3 alloys:

- Neodymium

- Iron

- Boron

Neodymium magnets have been commercially available since the mid-1980’s. Their high Maximum Energy Product and their wide range of available shapes, sizes, and grades are what make these magnets widely popular.

Manufacturing of Neodymium Magnets

Neodymium magnets can be manufactured by:

- Sintering

- Compression bonding

- Injection molding

- Extrusion

MAGNETIZING

- The sintered form holds the highest energy product of up to 55 MGOe

- The majority of neodymium magnets are anisotropic and can only be magnetized in the direction of orientation

Sizes & Shapes of Neodymium Magnets

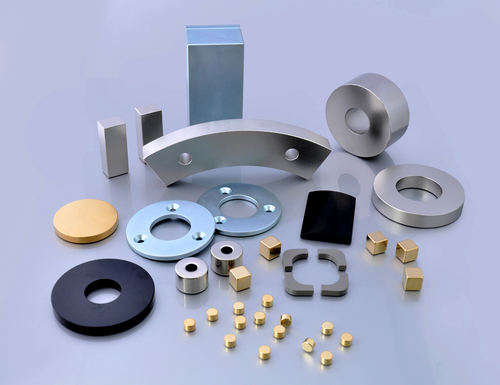

VERY MAGNET CUSTOM NEODYMIUM MAGNETS IN A VARIETY OF SHAPES AND SIZES, INCLUDING:

- Arc

- Bar

- Rod

- Disc

- Horseshoe

- Channel

- Block

- Ring

- Sphere

- Cylinders

- Plugs

Neodymium Magnet Plating & Coating Options

Neodymium magnets are prone to corrosion in humid environments.

For protective measures for corrosion resistance, Magnetic Hold offers plating and coating options.

Plating:

- Nickel

- Black Nickel

- Chemical Nickel

- Nickel + Epoxy

- Zinc

- Silver

- Gold

Coating:

- Epoxy

- Phosphate

- Phosphate + Parylene

- Phosphate + Teflon

- Plastic

To find out more information, request a quote here through our online form. For custom shapes and sizes, please send a drawing or sketch. If one is not available, we can work with you to create your custom magnets.

Magnetism Direction Options

We can offer several different magnetization directions, see below schematics. Their availability is limited to size. Magnetization fixture cost may apply for large and custom magnets with magnetization other than what is shown below

NEODYMIUM MAGNET GRADES & PROPERTIES

| GRADE | Residual Induction Br (max) [KGa] | Max Energy Product BH (max) MGOe | Coercive Force Hcb KOe | Curie Temp. [˚C] | Temp. Coe of Br [%/˚C) | Max. Practical Operating Temp. [˚C] | |||

|---|---|---|---|---|---|---|---|---|---|

| N33 | 10.8-11.3 | 28-31 | ≥10.0 | 310 | -0.11 | 80 | Quote | ||

| N35 | 11.7-12.2 | 33-36 | ≥10.9 | 310 | -0.11 | 80 | Quote | ||

| N38 | 12.2-12.5 | 36-39 | ≥11.3 | 310 | -0.11 | 80 | Quote | ||

| N40 | 12.5-12.8 | 38-41 | ≥11.4 | 310 | -0.11 | 80 | Quote | ||

| N42 | 12.8-13.2 | 40-43 | ≥11.5 | 310 | -0.11 | 80 | Quote | ||

| N45 | 13.2-13.8 | 43-46 | ≥11.6 | 310 | -0.11 | 80 | Quote | ||

| N48 | 13.8-14.2 | 46-49 | ≥11.6 | 310 | -0.11 | 80 | Quote | ||

| N50 | 14.0-14.5 | 48-51 | ≥10.0 | 310 | -0.11 | 80 | Quote | ||

| N52 | 14.3-14.8 | 50-53 | ≥10.5 | 310 | -0.11 | 80 | Quote | ||

| N55 | 14.5-15.0 | 51-55 | ≥10.5 | 310 | -0.11 | 80 | Quote | ||

Br: Residual Induction

Gs: Gauss

Hc: Coercive Force

Oe: Oersted

˚C: Degree Celcius

MGOe: Mega Gauss Oersted

Standard Tolerances (inches);

All shapes and sizes (±0.005)

Caution!

Extreme caution must be taken when working with rare earth magnets. Magnets larger than a few centimeters are strong enough to cause injuries to body parts pinched between two magnets, or a magnet and a metal surface, even causing broken bones. Magnets allowed to get too close to each other can strike one another with force to chip and shatter the brittle material, and the flying chips can cause injuries.